Piezo and Motor for Nanometer Precision

- Simultaneous control of piezo flexure drives and DC-servo/ball screw drives

- Repeatability in the nanometer range

- Direct metrology: Linear encoder with 2 nm resolution

- Millisecond settling time to nanometer precision

- Frictionless piezo drive and flexure decoupled ball screw

- Active compensation of backlash and stick-slip effects during approach

- High consistent velocity

- High drive and holding forces at minimum energy requirements / thermal dissipation

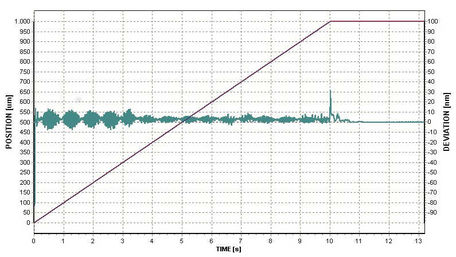

Stick-Slip Effects

Stick-slip effects when reaching the position or backlash can so be compensated for. The closed-loop control for both motion systems use the same high-resolution position sensor. The result is a motion system with hundreds of millimeters travel but with the precision of a piezo-based nanopositioner.

The resolution and the positioning accuracy depend on the choice of the position sensor used.

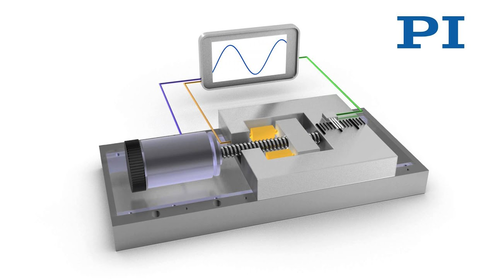

Decoupled Motion

In hybrid drives, the moving platform is decoupled from the motorized drive train by means of a highly stiff piezo actuator as well as backlash-free and frictionless flexure joints. In positioning mode, setting to a few nanometers only takes a few milliseconds, and minimal increments in the range of the encoder resolution can be reliably executed.

In dynamic operation, the piezo actuators guarantee a very constant velocity by compensating the irregularities in the motion of the motorized drive.

Applications

Hybrid stages are particularly suited for applications that need high accuracy for measuring and returning to a position or for surface inspection and metrology, to reach a target position accurately to the nanometer.