Motor-spindle combinations convert the rotary motion of the motor into linear motion, whereby the response times are delayed due to the backlash between the mechanical components. Drives such as PILine® however generate linear motion directly, with greater stability and less inertia.

PILine® drives dispense with the mechanical complexity of classical rotary motor/gear/spindle combinations in favor of costs and reliability. These components can be very susceptible to wear, especially in miniaturized systems.

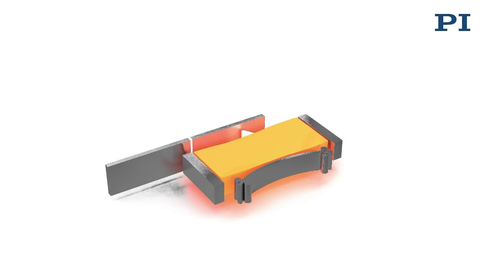

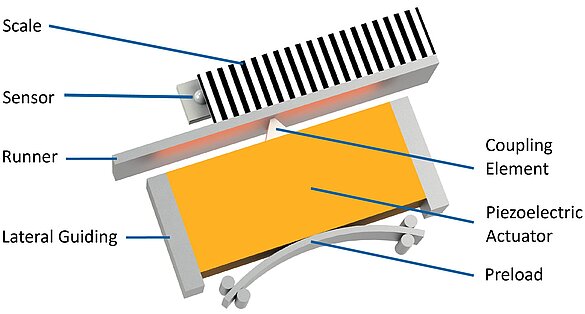

Operating Principle of PILine®

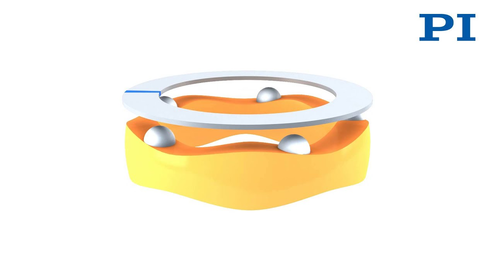

An integral part of the ultrasonic piezomotor is a piezo actuator that is pretensioned against a movably guided runner via a coupling element. The piezoceramic actuator is excited to ultrasonic vibrations with a high-frequency AC voltage between 100 and 200 kHz. Deformation of the actuator leads to a periodic diagonal motion of the coupling element, relative to the runner. The created feed is a few nanometers per cycle; the high frequencies lead to the high velocities.

Preloading the piezoceramic actuators against the runner ensures self-locking of the drive when at rest and powered down. As a result, it does not consume any power, does not heat up, and keeps the position mechanically stable. Applications with a low duty cycle that are battery operated or heat sensitive benefit from these characteristics.

Service Life and Reliability

The motion of the piezoceramic actuator is based on crystalline effects and is not subject to any wear. The coupling to the runner, on the other hand, is subject to friction effects. Depending on the operating mode, travel distances over 2,000 km or a MTBF of 20.000 hours are achieved.

Piezo Motors for All Applications

Piezomotors from PI are vacuum compatible in principle and suitable for operation under strong magnetic fields. Special versions of the drives are available for this purpose.

Low Profile Height

The benefits of the small design height of the PILine® drives becomes apparent with positioning systems such as the M-687 microscope cross table (25 mm height): A consistently flat design without spindle channels or flanged motors.

Dynamics in Use

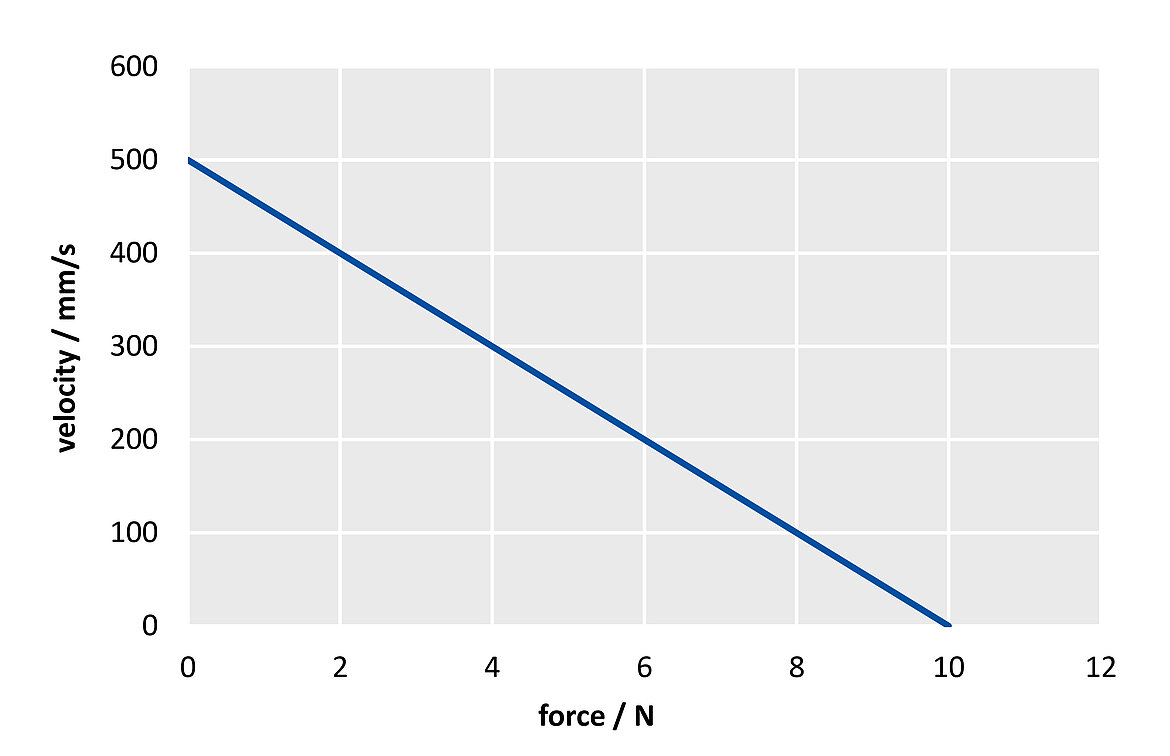

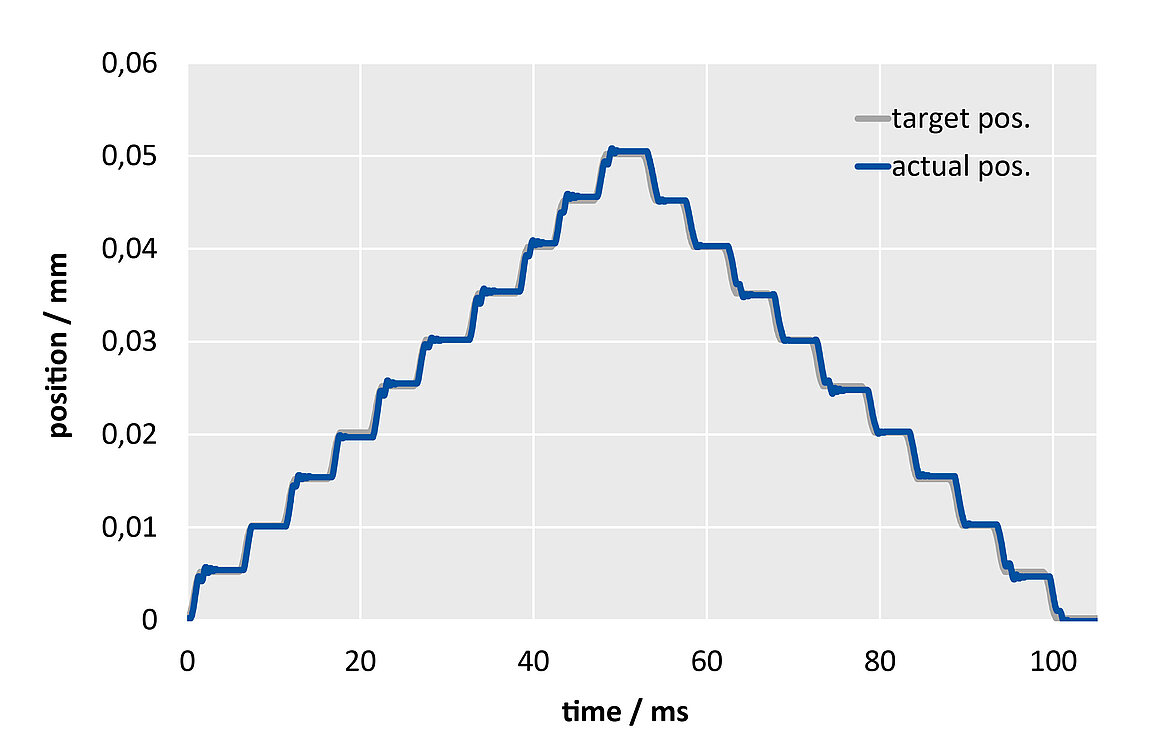

The direct-driven, robust design and fast response times of the piezo ceramics allows for very fast start / stop behavior and velocities to several 100 mm/s.

Slow Travel with PILine®

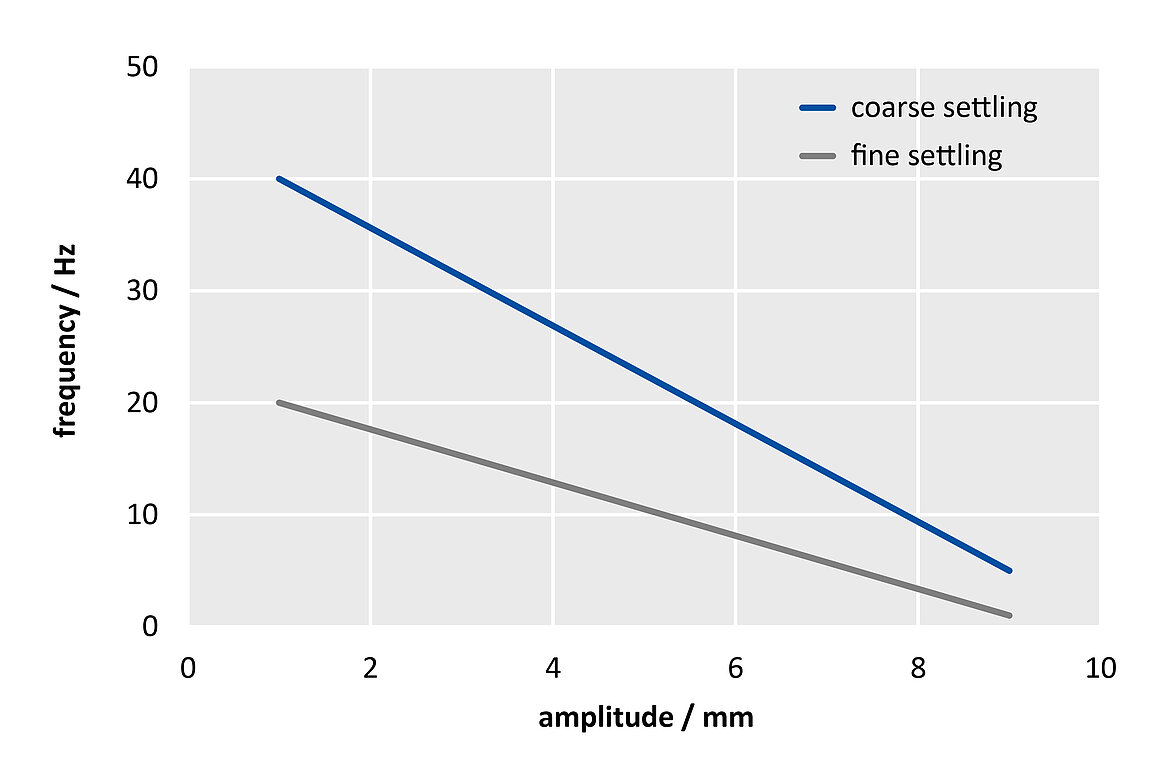

The demand for faster scanning speeds or greater throughputs characterizes only some of the applications in microscopy. Others demand high-resolution motion at low, constant speeds.

Stages with PILine® drives can be equipped with PIOne sensors and can achieve resolution in the range of single nanometers. Special control and regulation processes then provide constant speeds in the range of single encoder counts per second.

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Downloads

Advanced Motion Control with PILine®

Motion Control Capabilities of PILine® Ultrasonic Piezo Motor

Poster: PI Piezomotor Technology

Selection guide for the best solution

Reliability of PILine® Components

Lifetime, Wear and Reliability of PILine® Systems