Piezo Actuators Have Excellent Drive Properties

Piezo Actuators Have Excellent Drive Properties

- The movement of piezo actuators is based on solid-state effects, which means that their resolution is in principle unlimited.

- Their stiffness is very high, enabling high force generation and dynamics.

- Their rapid response time in the microsecond range is a result of their high resonant frequency of several hundred kilohertz.

- The available travel range is several hundred micrometers.

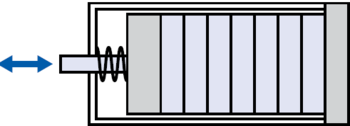

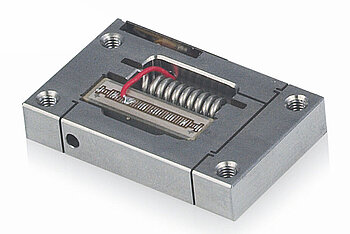

Piezoceramic actuators are insensitive to push forces, but must be protected against pulling and shearing stress. A housing can mechanically decouple lateral forces and insulate electrical contacting.

Preloading is, for example, applied using a spring between the housing and the piezo ceramic. This prevents pull forces as caused during dynamic operation by the inert mass of the load.

Flexure Guides Steer the Motion and Retain Stiffness

Flexure Guides Steer the Motion and Retain Stiffness

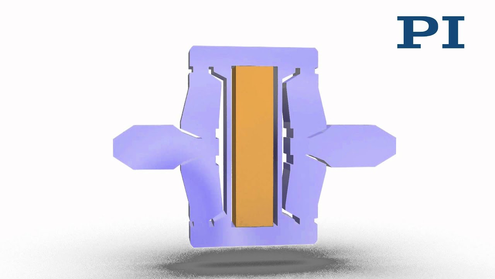

Precise straight motions require the piezo actuator to be embedded in a guide. This is usually a flexure guide, which is frictionless and allows hysteresis-free motion at the possible travel ranges of up to a few millimeters.

Ideally this mechanical guiding concept also integrates force decoupling and preloading without an adverse effect on the system stiffness.

Lever Amplification Allows Travel Ranges up to Several Millimeters

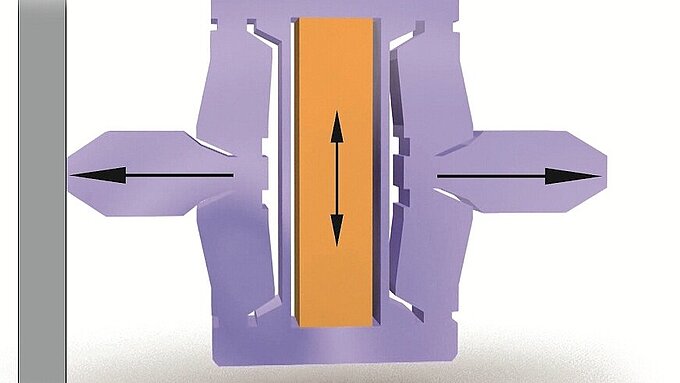

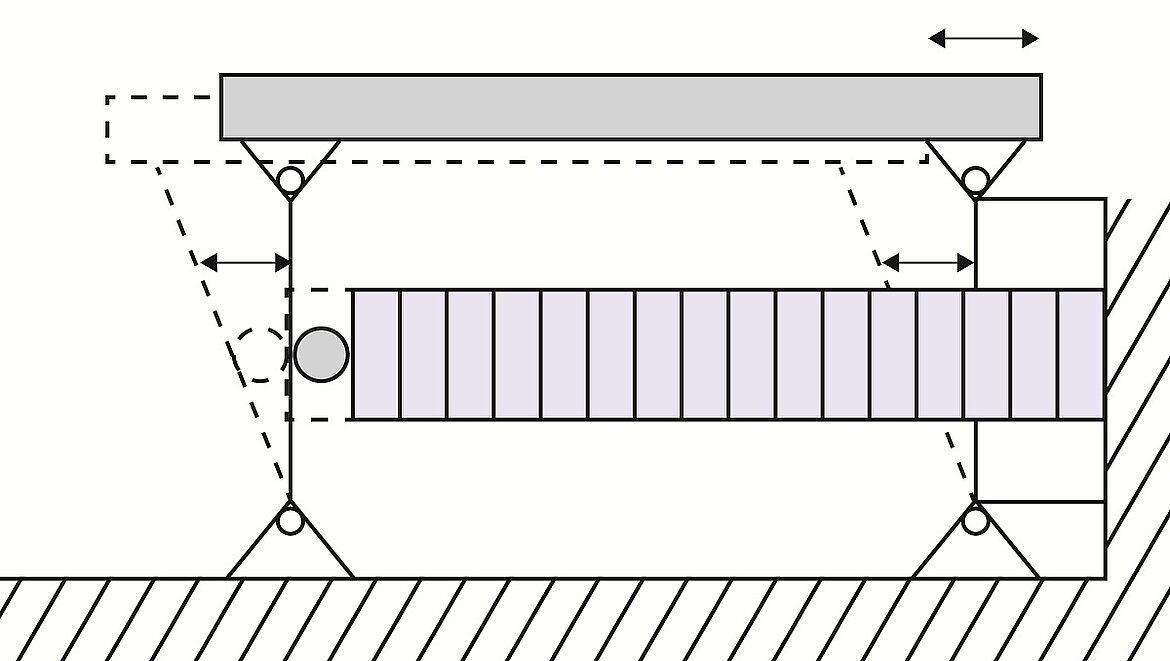

The displacement of piezo stack actuators is typically up to a few ten micrometers with a few 100 micrometers being the maximum. The flexure guide can be designed such that it will act like a mechanical lever. This mechanically amplifies the displacement of the piezo actuator and guides it into a different direction, if necessary.

Lever-amplified systems have an extremely demanding design: On the one hand, they are supposed to prevent lateral migration and, on the other, to always guide it in a straight line, even though the lever always leads through a pivot point.

Moreover, increasing the travel range is at the cost of stiffness. The flexure guide can be designed such that further integration does not require any additional guide. Flexure joints are employed as guiding and levering system, also in higher integrated piezo systems.

PiezoMove® OEM Lever Actuators with Built-In Guide

PiezoMove® actuators combine guided motion with long travel ranges of up to 1 mm as well as an optional sensor which provides precision up to 10 nanometers. The high-precision, frictionless flexure guides achieve very high stiffness as well as extremely low lateral displacement.

This makes them easier to handle than a simple piezo actuator, but still keeps them extremely compact. The number and size of the piezo actuators used determine stiffness and force generation. Due to these features, their small dimensions and the cost-effective design, the PiezoMove® lever actuators are particularly suitable for OEM applications.

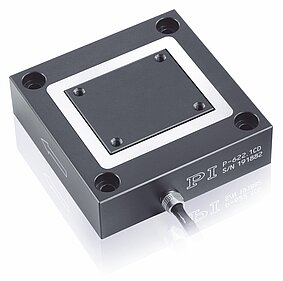

From a Stack Actuator to a 6-Axis Positioning System

PI offers various integration levels of piezo actuators. These range from the pure drive component via single-axis stages with integrated nanopositioning sensor to highly complex, multi-axis positioning stages with digital control.

| Stack actuators | Lever-amplified actuators | Positioning systems | |

|---|---|---|---|

| Travel ranges | up to approx. µm | to 1 mm | to 1 mm |

| Moving axes | one | one | up to 3 linear axes and 3 tip/tilt axes |

| Sensor technology | optional SGS | optional SGS | SGS or direct measuring |

| Linearity | up to 99.8 % | up to 99.8 % | more than 99.9 % |

| Guiding | none | Flexure joints for tilts <10° | Flexure joints for tilts <2° |

| Space requirement | low | low | depending on configuration |

| Price | low | low | depending on configuration |

| Integration effort | average | low | low |