Characteristics

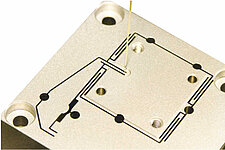

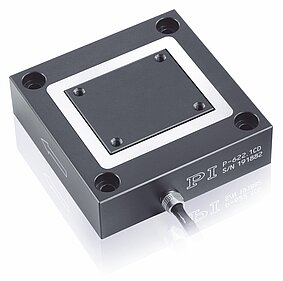

Their advantages are the high stiffness, load capacity, and wear resistance. Flexures are maintenance-free, can be manufactured from nonmagnetic materials , do not require lubricants or consumables and hence also function, without any problem, in a vacuum.

Flexures as Levers

The travel range of a piezo actuator can also be multiplied by integrating a lever mechanism. The actuator is mechanically integrated in a flexure joint in such a way that the travel range is extended to up to 2 mm. Since simple lever structures lose a considerable amount of guiding accuracy and stiffness, however, the design requires much more complex geometries.

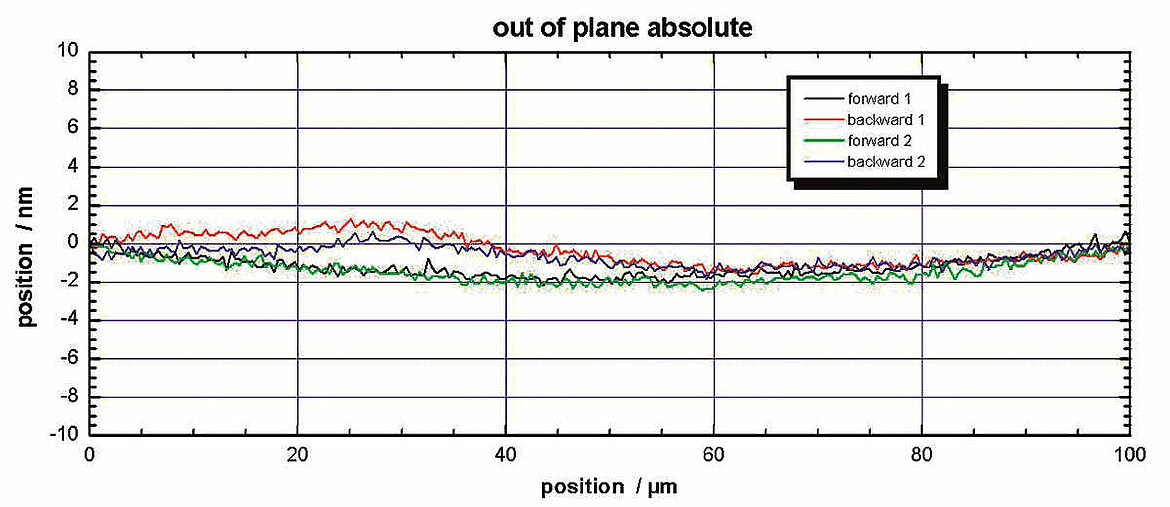

Subnanometer Accuracy

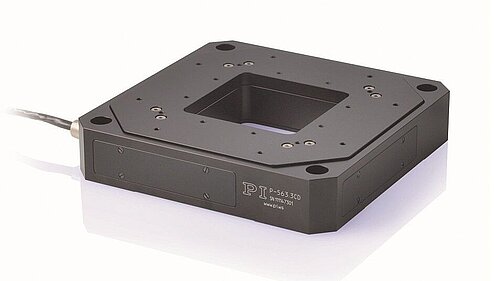

Flexures allow motions with extremely high path accuracy. To compensate for height or transversal offset, PI has developed special multi-link flexure guides. These guiding systems, which are used in most nanopositioning systems from PI, allow a flatness and straightness in the subnanometer or microradian range.