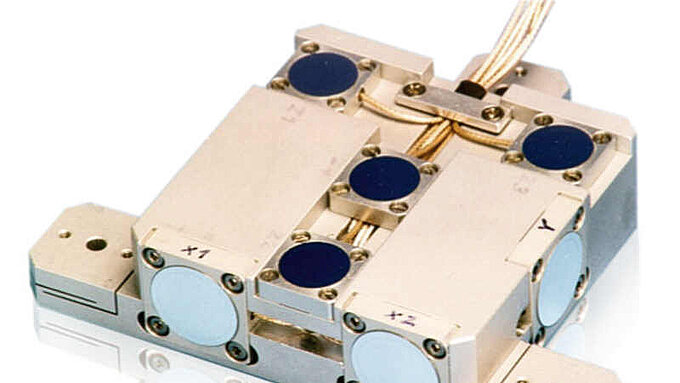

PI offers the widest range of high-dynamics and high-resolution nanopositioning systems worldwide. Their linearity and repeatability would not be possible without highest-resolution measuring devices.

Accuracies in the range of a few nanometers and below require a position measurement method that can also detect motion in this range. The most important specifications for selecting a suitable method are linearity, resolution (sensitivity), stability, bandwidth, and, last but not least, the costs. Another important factor is the ability to directly record the motion of the platform.

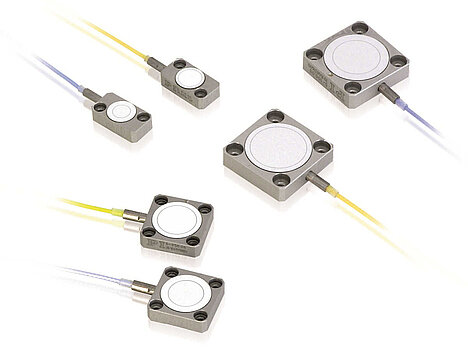

The contact with the movable parts also affects the measuring result; therefore, PI uses noncontact measurement methods as far as possible. Furthermore, the sensors need to be small and may not heat up. PI nanopositioning systems use four different types of sensors:

- Capacitive sensors

- Strain gauges sensors (SGS)

- Piezoresistive sensors (PRS)

- Linear encoders

| Capacitive | SGS | PRS | Linear Encoder | |

|---|---|---|---|---|

| Sensitivity / Resolution* | excellent | very good | excellent | excellent |

| Linearity | excellent | very good | good | very good |

| Stability / Repeatability | excellent | good | average | excellent |

| Bandwidth* | excellent | very good | very good | very good |

| Measurement method | direct / noncontact | indirect / with contact | indirect / with contact | direct / noncontact |

| Measurement range | <2 mm | <2 mm | <1 mm | up to >100 mm |

* The classifications refer to the characteristics of the nanopositioning system. The information on resolution, linearity, and repeatability in the respective data sheet reflect the specifications of the overall system, including controller, mechanics, and sensor. The checking is done with external measuring instruments (Zygo interferometer). This data must not be confused with the theoretical data of the sensor system.

Indirect Position Measurement with Strain Gauge Sensors (SGS)

Strain gauge sensors consist of a thin metal or semiconductor foil (piezo resistant), which is attached to the piezo ceramics or, for improved precision, to the guiding system of a flexure stage. This type of position measurement is done with contact and indirectly, since the position of the moving platform is derived from a measurement on the lever, guide or piezo stack. Strain gauge sensors derive the position information from their expansion. Full-bridge circuits with several strain gauge sensors per axis improve thermal stability.