Piezoelectric ceramic composites consist of a combination of piezoelectric ceramic and a filler polymer, merging the strengths of both materials. As a powerful alternative to solid ceramic components, they offer numerous advantages—particularly due to their high design freedom and flexibility. The polymer content allows for excellent adaptation to surrounding media with varying acoustic impedance. This opens up a wide range of applications: in medical technology, for example, in HIFU applications or diagnostic imaging, as well as in industry, such as flow measurement or nondestructive testing. Composites also provide improved ultrasound sensitivity and higher resolution.

Specifications

PI Ceramic’s composites are manufactured in a rigid 1-3 arrangement using the Dice & Fill technology. Dimensions and materials can be selected according to the customer-specific >> piezo components and can—after technical evaluation—be realized as composites. The feasibility assessment is based on the submitted requirements or dimensions.

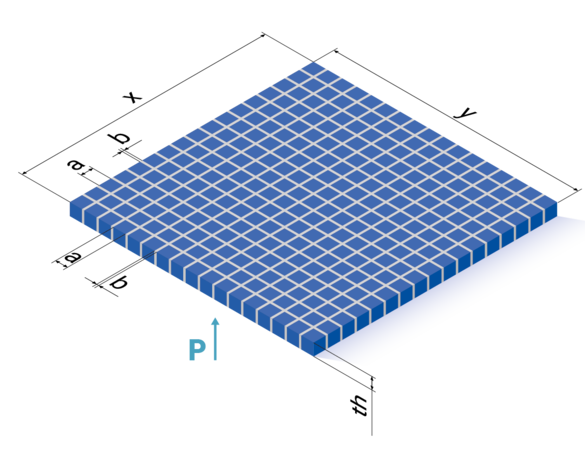

| Edge length x,y [mm] | < 80 |

| Thickness TH [mm] | > 0.1 - 16 |

| Gap dimension b [µm] | > 80 |

| Pin dimension a [µm] | > 200 |

| Pitch [µm] | > 200 (distance from pin center to next pin center) |

| Filling volume [%] | 30 - 80 (volume share of ceramic in total composite) |

| Frequency [MHz] | 0.08 - 8 |

| Electrodes | Thin layer (Ag, Au, CuNi, Ni) |

| Filling material | Epoxy resin, polyurethane |

| Termination | Various contact methods are available, such as bonding of wires and flexible printed circuit boards. |

| Material | We offer various ferroelectric soft and hard PTZ materials and lead-free alternatives. |

| Added capabilitites | In addition to refinement via assembly and interconnection techniques, tailored solutions can be developed, including

|

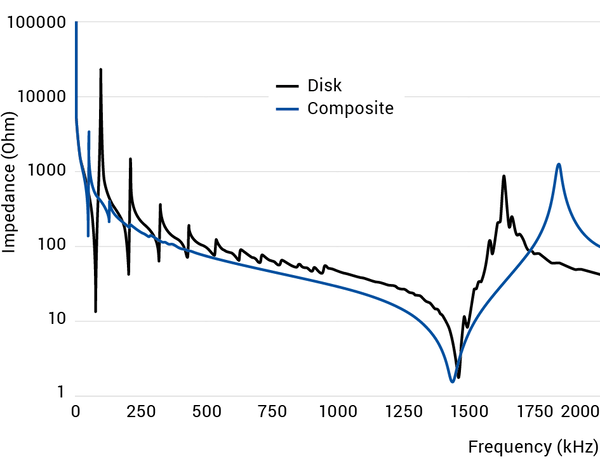

| Comparison to solid ceramics | By combining ceramic and polymer, composites offer higher electromechanical coupling and a broader bandwidth compared to solid ceramics. Additionally, they can be more easily adapted to media with varying acoustic impedance. Our >> piezo calculator is available for specification calculations. Comparative data for solid ceramics can be found >> here. Besides classic geometries such as plates, discs, or hemispheres, the composite structure also enables the implementation of more complex shapes. |

| Applications | Piezoelectric ceramic composites can replace solid ceramics in a wide range of applications. Examples of possible applications can be found >> here. |

Comparison of Properties: Solid Ceramic vs. Composite

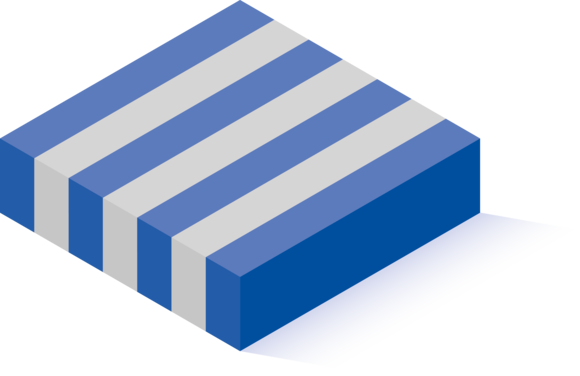

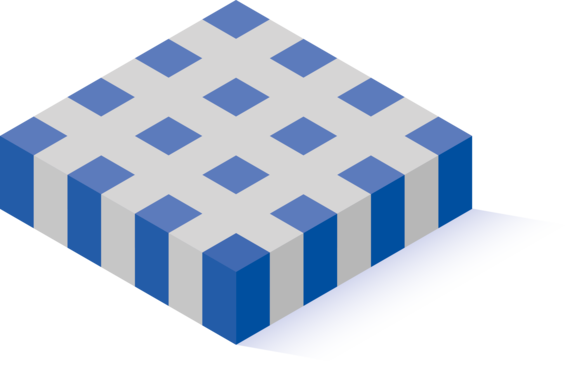

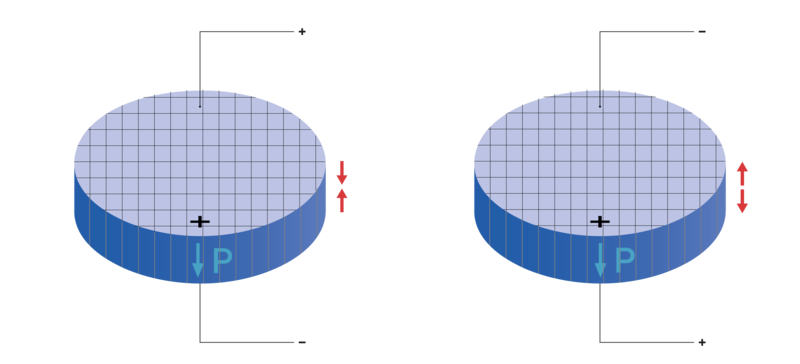

The combination of piezoelectric material and polymer in piezo components, such as discs, results in higher axial displacement (d33-effect) with minimal radial displacement.

Compared to a piezoelectric solid ceramic disc, composites show a reduction in acoustic impedance, resulting in improved coupling to water or organic tissue.

The capacitance is determined by the active total area of the body, the permittivity of the material, and the thickness.

| Resonant frequency (thickness) f [kHz] | Thickness TH (mm) | Pin dimension PIN (mm) | Piezoceramic share of volume (%) | Resonant impedance I (Ω) | Electrical capacitance C* (nF) | Dielectric loss factor tan δ (x10-3) | Coupling factor keff (%) |

|---|---|---|---|---|---|---|---|

| 400 | 4.0 | 1.0 x 1.0 | 83 | < 30 | 1.6 | < 20 | > 55 |

| 600 | 2.6 | 0.5 x 0.5 | 69 | < 15 | 2.1 | < 20 | > 60 |

| 1500 | 1.1 | 0.4 x 0.4 | 69 | < 5 | 5.0 | < 20 | > 55 |

| 2000 | 0.7 | 0.3 x 0.3 | 64 | < 3 | 6.5 | < 20 | > 55 |

*1000 kHz

Example specifications for a 1-3 epoxy resin composite disc with OD 25 mm made from piezo material PIC255.

- HIFU incisionless surgery & drug delivery

- Blood flow metering

- Ultrasonic imaging

- Cosmetic dermatology

- Sensor devices

- Hydroacoustics

- Non-destructive testing

Downloads

Material Data

Lead-Free Piezoceramic Materials

User Manual A000T0047

Handling and Electrical Contacting of Piezo Components