Six Axes of Motion with Hexapods and SpaceFAB

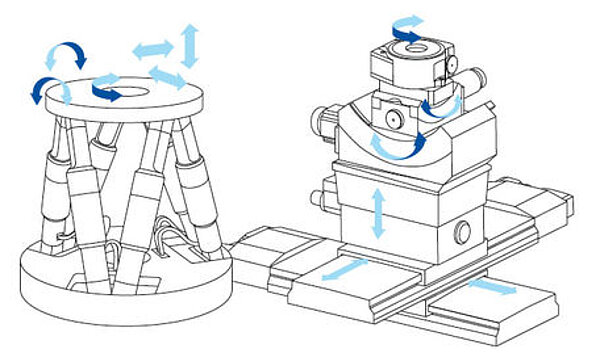

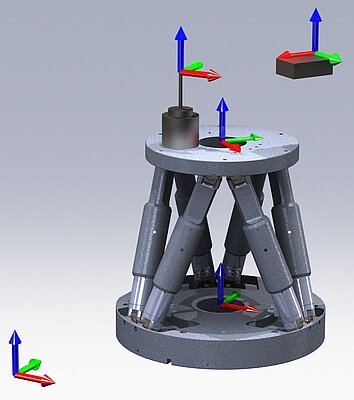

- Hexapod platforms are used for moving and precision positioning, aligning and displacing loads in all six degrees of freedom, i.e., three linear and three rotational axes. Hexapods have a parallel-kinematic structure, i.e., the six drives act together on a single moving platform.

- The length of the single drives is variable, allowing the system to move in all six degrees of freedom in space. This special hexapod design optimizes the overall system stiffness and allows a large central clear aperture.

- Depending on their design, hexapods can position loads from several kg to a few hundred kg or even several tons in any spatial orientation, that is, independently of the mounting orientation and with high precision.

Motors and Drives

PI hexapods are based on >> Piezoelectric or >> Electromechanical drives and are much more accurate than the hydraulic hexapods known from flight or driving simulators. Precision leadscrew drives or magnetic or piezo-based linear motors are used. Most systems are self-locking. Direct-drive hexapods ensure higher velocities; for industrial use, brushless motors (BLDC) are particularly suitable.

The application determines the drive technologies: Hexapods with piezoelectric >> PiezoWalk® Stepping Drives for ultrahigh vacuum applications and can also be operated in very strong magnetic fields.

For particulary high precision and low linear deflections and angles, >> Flexure Joints can be used. They work friction-free, play-free, and without the need of lubricants.

Joints

Joints

Hexapods for precision positioning often have cardanic joints with two orthogonally arranged axes. This is the optimum combination of two degrees of freedom and the stiffness of the structure. Ball-and-socket joints offer more degrees of freedom in a relatively simple design. However, the overall stiffness and precision can suffer in case of external loads and torque. A compensating preload is recommended but requires drives with high output forces such as >> NEXLINE® Piezo Motor Drives.

Work Space

Work Space

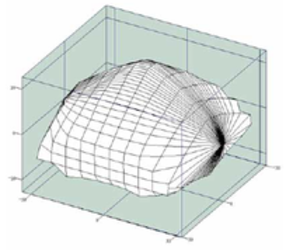

The entirety of all combinations of translations and rotations that a hexapod can approach from any given position is called the workspace; it is given in reference to the origin of the coordinate system used. The workspace can be limited by external factors such as obstacles or the dimensions and position of the load.

PI offers >> Software Tools that simulate the workspace and that can check eventual collisions with objects in the environment.

Advanced Motion Control

Advanced Motion Control

The individual drives of a hexapod do not necessarily point in the direction of motion, which is why a powerful controller that can handle the required coordinate transformations in real time is needed.

PI uses advanced digital controllers along with user-friendly software. All motion commands are specified in Cartesian coordinates, and all transformations to the individual actuators take place inside the controller.

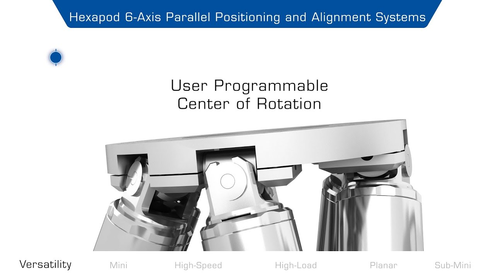

An important hexapod property is the freely definable pivot point. The possibility to rotate around any point in space opens up new application possibilities, and the hexapod platform can be integrated in the overall process.

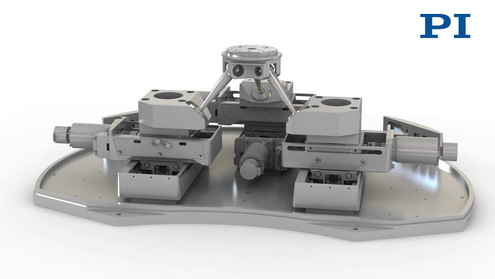

| Hexapod | SpaceFAB | |

|---|---|---|

| Design | 6 struts with variable length or moving joints act on a moving platform | 3 XY act in parallel on a moving platform |

| Geometry | Compact surface | Low height |

| Linear travel ranges in a plane | Limited | Flexibly by selecting XY stages |

| Linear vertical travel range | Long | Limited |

| Rotatory travel ranges | Large tilt around X and Y axes possible | Limited |

| Stiffness | High vertical stiffness | High stiffness in X and Y |

| Parallel-kinematics | Serial stacked design | |

|---|---|---|

| Dimensions | Compact set-up | Relatively high set-up, stabilization at base required |

| Moved mass | Platform plus load | Each stage carries the ones positioned on top plus the load and has to be designed accordingly |

| Dynamics / stiffness | Due to the low moved mass, relatively high, the same for all motion axes | Dynamic axes should be places as far on top as possible |

| Accuracy | The same for all motion axes | Errors add up from "bottom" to "top", high parallel error due to set-up height |

| Cable management | No moving cables, no effect on accuracy | Required |

| Commands | PI motion controllers can be used to save commands in Cartesian coordinates; they transform these commands into the motion of the individual struts | Cartesian, individually for each axis |

| Pivot point | Any point in space can be selected by means of PI software | Defined by selection of stage geometries |

| Work space | Generally limited | Defined by selection of stage geometries |

Hexapods in Automation: Control and Interfaces for Easy Integration

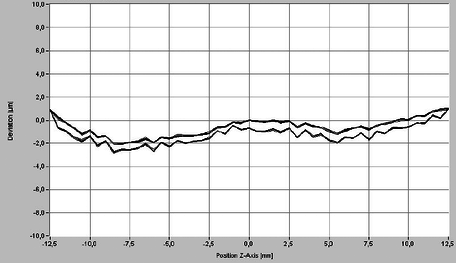

Precision path control with jerk limiting

The hexapod controller makes motion possible on the basis of complex trajectories with defined velocity and acceleration. Like this, hexapods in mechanical engineering can, for example, move a workpiece or tool jerk controlled and with high precision during machining without the mechanical system starting to vibrate.

User-Defined Coordinate Systems

To adapt the trajectory perfectly to the requirements of the application, it is possible to define various coordinate systems which refer, for example, to the position of workpiece or tool. This offers great advantages for applications in industrial automation, but also for fiber alignment.

Interfaces

EtherCAT interface: Standardized >> Fieldbus Interfaces guarantee an easy connection to parent PLC or CNC controls so that hexapods can work synchronously with other components in one automation line.