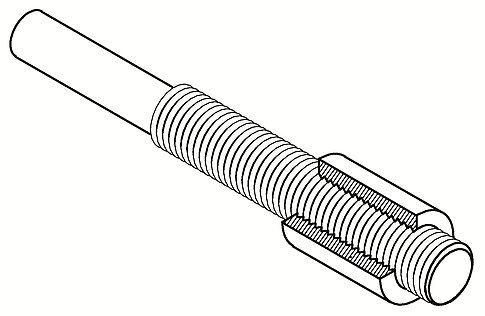

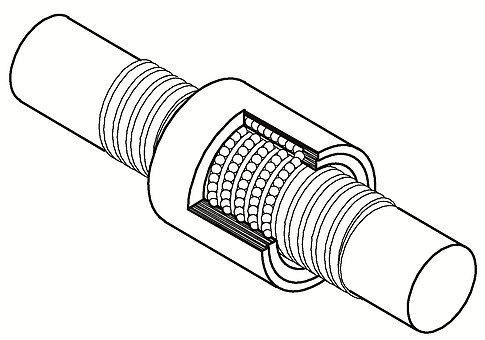

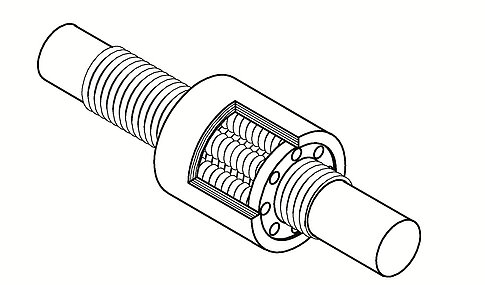

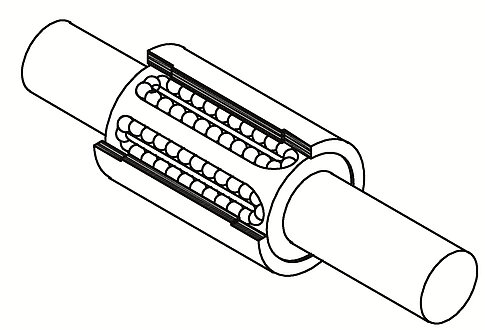

Leadscrews can provide very high resolutions and very smooth motion. A leadscrew drive consists of a motor-driven screw with a nut coupled to the sled of the stage. The nut can be spring preloaded to reduce backlash. They have higher friction than recirculating ball screws so that they are self-locking; on the other hand, however, this has an effect on velocity, motor power, and lifetime. Typical leadscrews have a pitch between 0.4 and 0.5 mm/revolution, up to 1 mm/revolution for longer travel ranges.

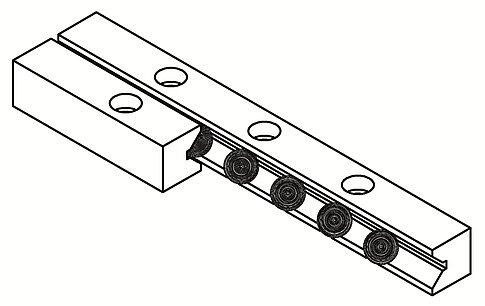

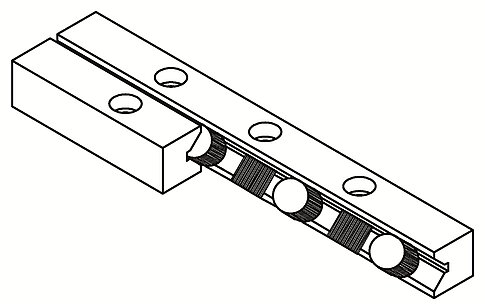

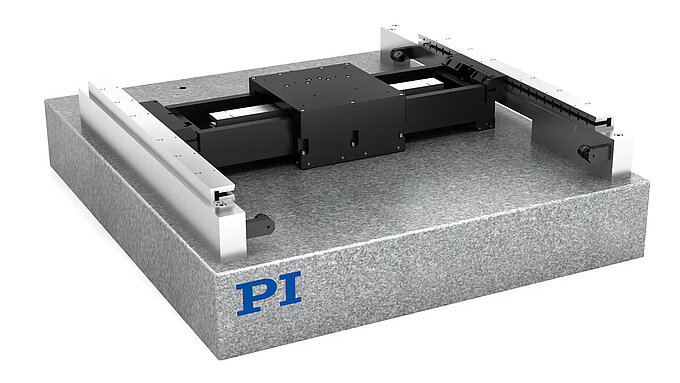

Positioners with travel ranges of several millimeters up to one meter generally utilize classical mechanical guide components such as ball bearings. In the case of linear positioning stages, the use of rotating motors such as DC or stepper motors requires transmission of motion using a spindle. If these mechanical elements are used, then precision is generally limited to the range of a micrometer.