Solving the Challenges in MicroLED Manufacturing with Fast and Precise Motion Control Solutions

A more lightweight and flexible design, less energy consumption, higher resolution and even more contrast and brilliance: This is what future display technologies should deliver in order to fulfill the requirements for function, handling, and lifetime. For example, it's about further improving the closeness to the eye and the independent viewing angle of head-up displays for augmented and virtual reality applications, making wearables such as smart watches more compact, robust, and energy efficient, but it is also about increasing the color intensity and brilliance of large-area screens and display panels.

Display Technologies in Comparison: LCD – LED – OLED – MicroLED

Currently, liquid crystal displays (LCDs) are dominant on the market. With this technology, each pixel is generated by three subpixels in the RGB colors, red, green, and blue. LEDs, which are light-emitting diodes, are here only used as white light variants as background color. Also colored LEDs can be manufactured, however, because of their size, they are only suitable for large-scale screens.

MicroLED displays are made of arrays of microscopically small red, green, and blue LEDs, where each LED corresponds to one pixel on the display. The pixels are self-luminescent, dimmable, and can be switched off completely, similar to OLED- and plasma displays, and therefore do not need any background illumination. In contrast to OLEDs, MicroLEDs are based on the gallium nitride technology, which offers a 30-times higher overall brightness as well as a higher efficiency in Lux/W and therefore a lower current consumption than OLEDs. Essential advantages of MicroLEDs are also the higher color saturation and lower sensitivity to oxygen and moisture, so that encapsulation is not required.

Challenges of Mass Production

A MicroLED display is made of millions of tiny pixels. In order to exploit the potential of the MicroLED technology and make an economically viable mass production possible, manufacturers must overcome many challenges given by the extremely small sizes, function, and quantity of the components.

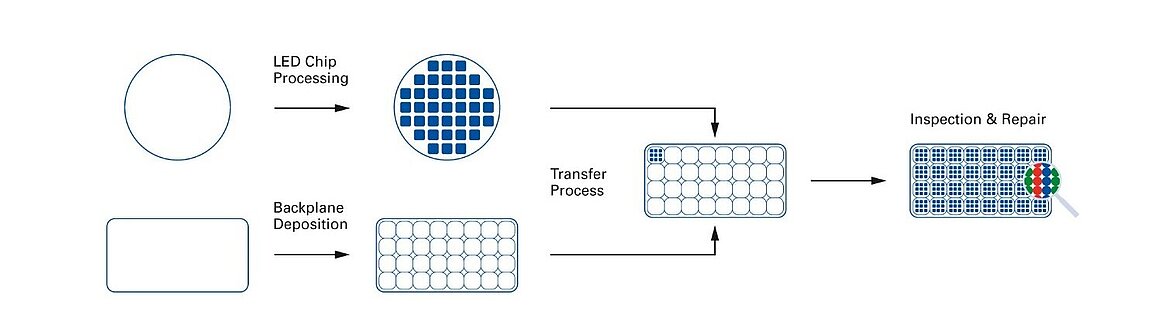

To manufacture a display, MicroLED wafers must first be generated by epitaxial growth. In a special pick-and-place process, thousands and thousands of LED chips (arrays) of a few micrometers in size are picked up and transferred to a substrate or backplane. This requires a fast, precise, and reliable transfer process – one of the main challenges of the MicroLED manufacturing. Devices are necessary for placing the individual arrays that can position with an accuracy of ±1.5 µm. This means that the manufacturers must develop processes that deliver high quality with microscopic accuracy while reaching the speeds for mass production.

Another critical point is the pixel yield. Dead pixels can occur in different stages of the manufacturing process, so that inspection and repair should not only take place at the end of the process but also during the entire manufacturing process in order to ensure uniform luminance (brightness) and wavelength (color). In order to achieve a rate of less than five dead pixels per RGB color display with full resolution (1920 x 1080 pixels), a yield of 99.9999 % is required.

For inspection imaging systems can detect and analyze the luminance of MicroLED chips. Here also, the challenge is the required precision and speed. Current solutions for repairing MicroLEDs are technologies such as ultraviolet radiation or selective laser techniques.

To meet the high demands for precision and speed, PI supports research groups and manufacturers worldwide with motion, control and software solutions. With many years of experience in precision positioning, a wide range of technologies and a high level of vertical integration, PI is able to select the most suitable approach to solve the challenges customers are faced with.

Parallel kinematic solutions such as hexapods are providing precision alignment between LED and substrate. Air bearings motion platforms offer demanding continuous XY accuracy between wafers, and for the ultimate in speeds while maintain single digit micron performance, gantry systems offer the optimal performance.

PI’s system engineers are assisting customers in both their design and production planning phases. The PI team is ready to configure customer specific solutions that further optimize production processes driving the commercialization of the new generation of displays. Worldwide production and service locations ensure that reliability and quality of delivery and performance are ensured - even with changing requirements and production volumes.