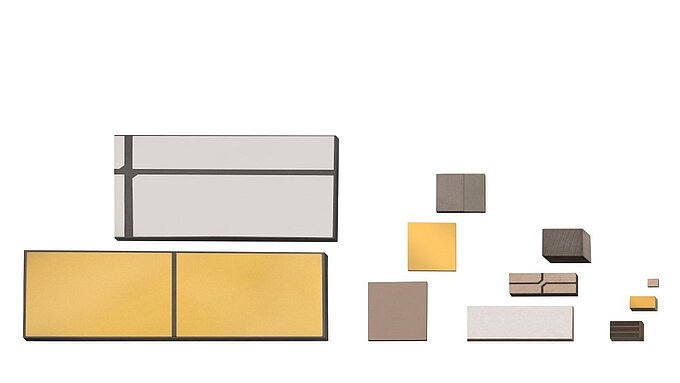

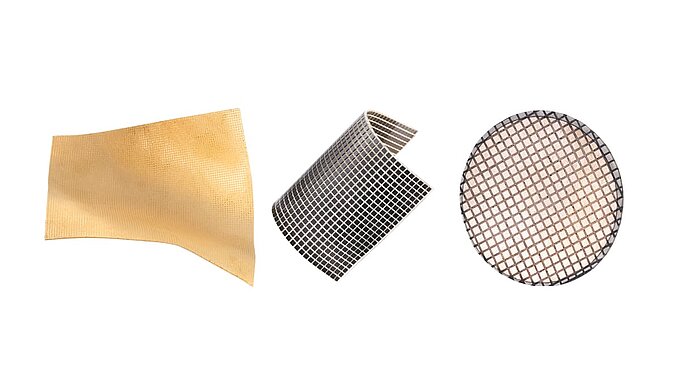

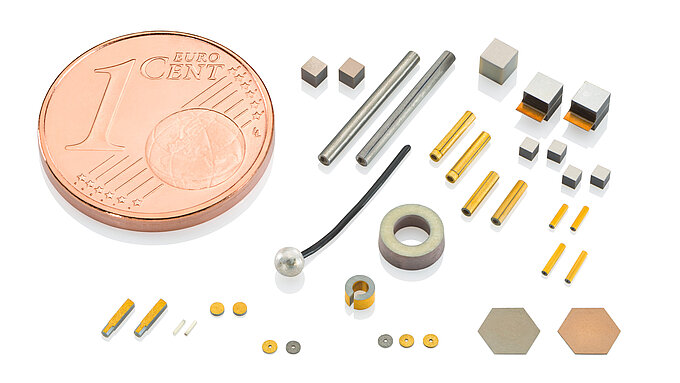

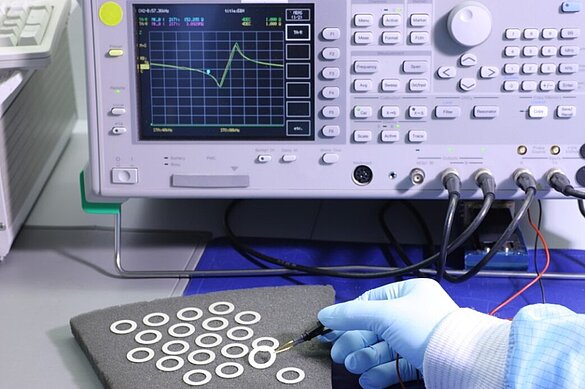

Piezoceramic components for ultrasonic transducers are available in various sizes and geometries. Whether standard components or customized components, piezo elements can be used in a wide range of applications in industry, medical technology, and microscopy. Alongside bulk components, PI Ceramic offers flexible composites that can be adapted to complex shapes. And depending on the specifications and application, these composites can also be used to produce customized >> ultrasonic transducers and ultrasonic sensors.

Transducer Component Specifications

The specifications and mode of action of piezo components depend on their geometry, electrode design, contacting, >> material, and size. PI Ceramic has several standard components with different designs and specifications.

Customized Versions on Request

PI Ceramic possesses extensive know-how, from the selection of suitable materials to the development and manufacturing of components and ultrasonic transducers. The focus is always on the customer's application. PI Ceramic's expertise lies in manufacturing with specially developed >> piezoceramic materials, continuously optimizing these materials, and developing lead-free materials.

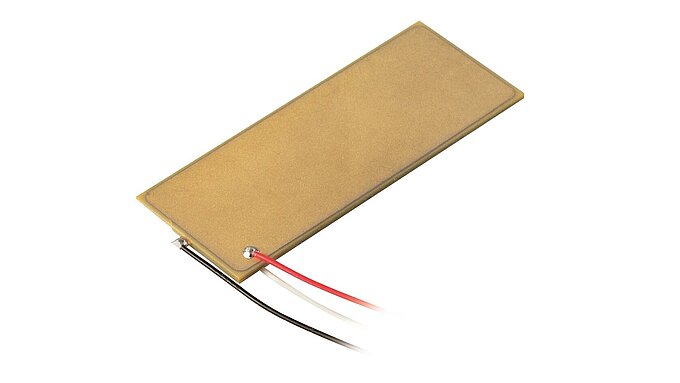

Various options are available for selecting the electrode design, such as sputtered copper-nickel (CuNi) or gold connections, and insulated single or full-surface electrodes. Upon request, PI Ceramic can also offer more highly refined designs—be it soldering stranded wires and flexible printed circuit boards, bonding to substrates, or assembling ultrasonic transducers with acoustically matched coatings and housings.

What are your specific requirements?

Discuss your project specifications with our sales engineers.

Applications of Piezoceramic Ultrasound Components

Piezoelectric bulk components or piezocomposites have many different uses in ultrasonic transducers. Alongside their use in microscopy, these include: