6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes

C-887.52x Hexapod Motion Controller

Compact benchtop device for controlling 6-axis parallel kinematics

- Sophisticated controller using vector algorithms

- Commanding in Cartesian coordinates

- Easy customization of coordinate systems by command

- High-resolution analog inputs and motion stop as an option

- Extensive Software Package

Digital controller for 6-axis parallel kinematics

High-performance digital controller for controlling hexapods (6-axis parallel kinematics). Supports various drive types as the controller only provides the control signals, whereas the motor drivers are located in the hexapod or in a separate driver box. In addition, the motor drivers for two further single axes can be controlled.

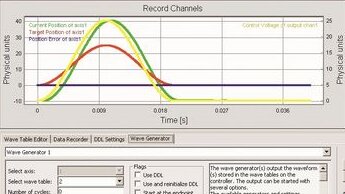

Functions

The position is entered in Cartesian coordinates from which the controller calculates the control of the kinematics. To simplify integration of the hexapod, the coordinate systems (Work, Tool) can be changed. The pivot point can be freely defined. A data recorder can record operating data, e.g., motor control, velocity, position, or position error. The execution of macros and Python scripts on the controller enables stand-alone operation. The controller supports all currently available standard hexapods from PI and, in addition, customer-specific parallel kinematics.

Interfaces

TCP/IP for network-based control and maintenance. RS-232. USB port for manual control unit.

Additional interfaces (depending on version):

- High-resolution and extremely fast analog inputs which are ideal for fast alignment routines

- Connection for a motion stop button that activates/deactivates the 24 V output for the hexapod

Optional

- Control via manual control unit

Extensive software support

For example, PIMikroMove user software enables fast alignment routines to be depicted graphically. GCS 2.0 command set for PI positioning systems. Extensive set of drivers, e.g., for use with C, C++, C#, NI LabVIEW, MATLAB, and Python. PIHexapodEmulator for virtual startup and operation without hardware.

Scope of delivery

The scope of delivery includes the controller, a software package, and a power adapter for the power supply. It is recommended to order the hexapod mechanics and a suitable cable set together with the controller so that the components can be adapted to each other.

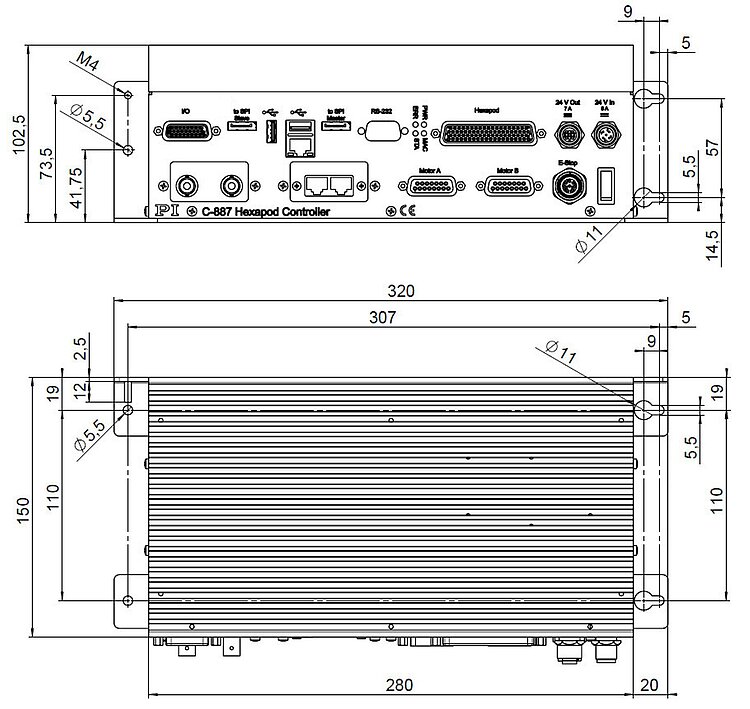

Specifications

Specifications

| Basics | C-887.52 | C-887.521 | C-887.522 | C-887.523 | |

|---|---|---|---|---|---|

| Axes/channels | 6 | 6 | 6 | 6 | |

| Additional axes | 2 single axes | 2 single axes | 2 single axes | 2 single axes | |

| Processor | Intel Atom dual core (1.8 GHz) | Intel Atom dual core (1.8 GHz) | Intel Atom dual core (1.8 GHz) | Intel Atom dual core (1.8 GHz) | |

| Application-related functions | Controller macros GCS ǀ Controller macros PIPython ǀ Data recorder ǀ Startup macro | Controller macros GCS ǀ Controller macros PIPython ǀ Data recorder ǀ Fast alignment ǀ Startup macro | Controller macros GCS ǀ Controller macros PIPython ǀ Data recorder ǀ Startup macro | Controller macros GCS ǀ Controller macros PIPython ǀ Data recorder ǀ Fast alignment ǀ Startup macro | |

| Protective functions | Switch-off of the servo mode in case of an error | Switch-off of the servo mode in case of an error | Switch-off via an external switch ǀ Switch-off of the servo mode in case of an error | Switch-off via an external switch ǀ Switch-off of the servo mode in case of an error | |

| Configuration management | reading the ID chip ǀ manual parameter input | reading the ID chip ǀ manual parameter input | reading the ID chip ǀ manual parameter input | reading the ID chip ǀ manual parameter input | |

| Supported ID chip | ID chip 2.0 | ID chip 2.0 | ID chip 2.0 | ID chip 2.0 | |

| Motion and Control | C-887.52 | C-887.521 | C-887.522 | C-887.523 | |

| Supported sensor signal | A/B quadrature, RS-422 ǀ BiSS-C | A/B quadrature, RS-422 ǀ BiSS-C | A/B quadrature, RS-422 ǀ BiSS-C | A/B quadrature, RS-422 ǀ BiSS-C | |

| Closed-loop values | Position | Position | Position | Position | |

| Maximum control frequency (servo cycle) | 10000 Hz | 10000 Hz | 10000 Hz | 10000 Hz | |

| Motion types | Point-to-point motion with profile generator ǀ Cyclic transfer of target positions ǀ Area scan routines ǀ Gradient search routines ǀ Wave generator | Point-to-point motion with profile generator ǀ Cyclic transfer of target positions ǀ Area scan routines ǀ Gradient search routines ǀ Wave generator | Point-to-point motion with profile generator ǀ Cyclic transfer of target positions ǀ Area scan routines ǀ Gradient search routines ǀ Wave generator | Point-to-point motion with profile generator ǀ Cyclic transfer of target positions ǀ Area scan routines ǀ Gradient search routines ǀ Wave generator | |

| Motion coordination | Coordinated multi-axis motion ǀ User-defined coordinate systems ǀ Work-and-tool coordinate systems | Coordinated multi-axis motion ǀ User-defined coordinate systems ǀ Work-and-tool coordinate systems | Coordinated multi-axis motion ǀ User-defined coordinate systems ǀ Work-and-tool coordinate systems | Coordinated multi-axis motion ǀ User-defined coordinate systems ǀ Work-and-tool coordinate systems | |

| Reference switch input | TTL | TTL | TTL | TTL | |

| Limit switch input | TTL | TTL | TTL | TTL | |

| Interfaces and Operation | C-887.52 | C-887.521 | C-887.522 | C-887.523 | |

| Communication interfaces | RS-232 ǀ TCP/IP ǀ USB (only for manual control units) | RS-232 ǀ TCP/IP ǀ USB (only for manual control units) | RS-232 ǀ TCP/IP ǀ USB (only for manual control units) | RS-232 ǀ TCP/IP ǀ USB (only for manual control units) | |

| On/off switch | Hardware switch on/off | Hardware switch on/off | Hardware switch on/off | Hardware switch on/off | |

| Display and indicators | Status LED ǀ Error LED ǀ Power LED ǀ Macro LED | Status LED ǀ Error LED ǀ Power LED ǀ Macro LED | Status LED ǀ Error LED ǀ Power LED ǀ Macro LED | Status LED ǀ Error LED ǀ Power LED ǀ Macro LED | |

| Manual control(s) | Manual control unit with USB interface | Manual control unit with USB interface | Manual control unit with USB interface | Manual control unit with USB interface | |

| Command set | GCS 2.0 | GCS 2.0 | GCS 2.0 | GCS 2.0 | |

| User software | PIMikroMove | PIMikroMove | PIMikroMove | PIMikroMove | |

| Software - APIs | C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python | C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python | C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python | C, C++, C# ǀ MATLAB ǀ NI LabView ǀ Python | |

| Analog inputs | 4 | 6 | 4 | 6 | |

| Analog input signal | 4 x -10 to 10 V, 12 bit | 2 x -5 to 5 V, 16 bit, 5 kHz bandwidth ǀ 4 x -10 to 10 V, 12 bit | 4 x -10 to 10 V, 12 bit | 2 x -5 to 5 V, 16 bit, 5 kHz bandwidth ǀ 4 x -10 to 10 V, 12 bit | |

| Digital inputs | 4 | 4 | 4 | 4 | |

| Digital input signal | TTL | TTL | TTL | TTL | |

| Digital outputs | 4 | 4 | 4 | 4 | |

| Digital output signal | TTL | TTL | TTL | TTL | |

| Electrical Properties | C-887.52 | C-887.521 | C-887.522 | C-887.523 | |

| Output voltage | 24 V | 24 V | 24 V | 24 V | |

| Peak output current | 6000 mA | 6000 mA | 6000 mA | 6000 mA | |

| Miscellaneous | C-887.52 | C-887.521 | C-887.522 | C-887.523 | |

| Connector hexapod power supply | M12 4-pole (f) | M12 4-pole (f) | M12 4-pole (f) | M12 4-pole (f) | |

| Connector hexapod data transmission | HD D-sub 78 (f) | HD D-sub 78 (f) | HD D-sub 78 (f) | HD D-sub 78 (f) | |

| Connector additional axes | D-sub 15 (f) | D-sub 15 (f) | D-sub 15 (f) | D-sub 15 (f) | |

| Connector analog input | HD D-sub 26 (f) | BNC ǀ HD D-sub 26 (f) | HD D-sub 26 (f) | BNC ǀ HD D-sub 26 (f) | |

| Connector digital input | HD D-sub 26 (f) | HD D-sub 26 (f) | HD D-sub 26 (f) | HD D-sub 26 (f) | |

| Connector digital output | HD D-sub 26 (f) | HD D-sub 26 (f) | HD D-sub 26 (f) | HD D-sub 26 (f) | |

| Connector motion stop button | — | — | M12 8-pole (f) | M12 8-pole (f) | |

| Connector TCP/IP | RJ45 socket, 8P8C | RJ45 socket, 8P8C | RJ45 socket, 8P8C | RJ45 socket, 8P8C | |

| Connector RS-232 | D-sub 9 (m) | D-sub 9 (m) | D-sub 9 (m) | D-sub 9 (m) | |

| Connector for supply voltage | M12 4-pole (m) | M12 4-pole (m) | M12 4-pole (m) | M12 4-pole (m) | |

| Operating voltage | 24 (ext. power adapter included) V | 24 (ext. power adapter included) V | 24 (ext. power adapter included) V | 24 (ext. power adapter included) V | |

| Power adapter | Included in the scope of delivery ǀ Power adapter 24 V DC | Included in the scope of delivery ǀ Power adapter 24 V DC | Included in the scope of delivery ǀ Power adapter 24 V DC | Included in the scope of delivery ǀ Power adapter 24 V DC | |

| Maximum current consumption | 8 A | 8 A | 8 A | 8 A | |

| Operating temperature range | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | 5 to 40 °C | |

| Overall mass | 2800 g | 2800 g | 2800 g | 2800 g |

Downloads

Product Note

Product Change Notification C-887.5xx Labeling

Datasheet

Documentation

User Manual A000T0079

PI Simulation Models for CoppeliaSim / V-REP

User Manual C887T0036

C-887.MC2 Manual Control Unit

User Manual MS244

C-887 Hexapod Controller, Models C-887.52, C-887.521, C-887.522, C-887.523, C-887.53, C-887.531, C-887.532, C-887.533

Technical Note C887T0021

Motion of the Positioner. Position and Orientation in Space, Center of Rotation.

User Manual C887T0007

Description of Coordinate Systems for Hexapod Microrobots and Parallel-Kinematic Positioners

User Manual E712T0016

Fast Multi-Channel Photonics Alignment of Silicon Photonics Components with F-712 Alignment Systems and Hexapods from PI. PILightning Option for First Light Search

User Manual C887T0001

Description of PIHexapodEmulator software

3D Models

C-887.52x 3D Model

Software Files

PI Software Suite C-990.CD1

C-990.CD1 Releasenews

General Software Documentation

User Manual A000T0075

Implementing a C-887 PI Controller in TwinCAT 3.1

User Manual A000T0028

Updating PI Software with PIUpdateFinder

Software Manual SM146

GCS Array Data Format

Software Manual SM148

PIMikroMove

Software Manual SM151

PI GCS DLL

Software Manual SM155

PI MATLAB Driver GCS 2.0

Software Manual SM156

PIStages3Editor for editing the PIStages3 database

User Manual A000T0067

Information on the PIStages3 database. What must be considered when changing from PIStages2 to PIStages3.

Software Manual SM157

PIPython - Programming PI Controllers with Python

Software Manual SM158

PI GCS2 Driver Library for NI LabVIEW

Technical Note A000T0089

PI Software on ARM-Based Platforms

User Manual SM163

PIVirtualMove. Simulation program for parallel-kinematic multi-axis systems

User Manual SM164

Updating controller firmware with PIFirmwareManager

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes, analog inputs

6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes, motion stop

6-axis controller for hexapods, TCP/IP, RS-232, benchtop device, incl. control of two additional axes, motion stop, analog inputs

How to Get a Quote

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

Technology

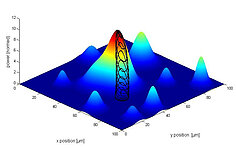

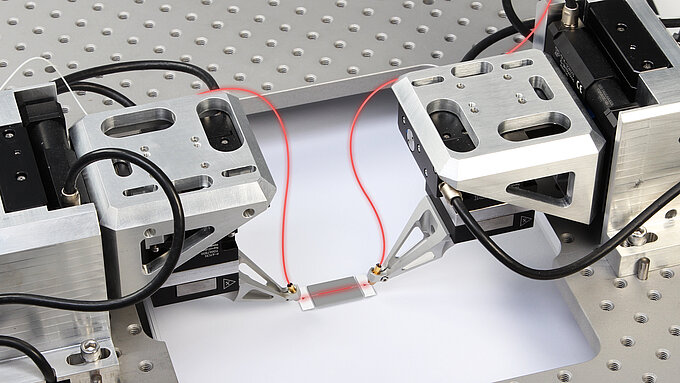

Active Alignment

The need to align devices down to nanoscale accuracy is arising in many fields. Optical components such as the lenses or lens assemblies in small cameras, or even the CCD chip itself, need to be positioned with ever more precision.

Digital Motion Controllers

Digital technology opens up possibilities for improving performance in control engineering which do not exist with conventional analog technology.

Digital & Analog Interfaces

Fast USB or TCP/IP interfaces as well as RS-232 are the standard interfaces supported by modern digital controllers from PI. Furthermore, PI also provides digital or analog real-time capable interfaces.